Construction Type Bio-safety Laboratory

Construction, Testing, Commissioning and Validation of Bio-safety Laboratory & associated works on “Turnkey Basis” in compliance with CDC, USA guidelines.

Construction and establishment of Bio-safety laboratory facility including civil works, electrical works, Public health engineering works etc. complete in all respect. All the fixed equipment and system like Autoclave, Bio-Safety Cabinets, Pass Box, dunk tanks, HVAC system and its components (including A/C plant, air handlers, exhaust systems, filters, controls etc.), Hot water generator (for hot water shower during winters), Air compressor, Computers, Laboratory workstations, Uninterrupted power supply system, door interlocks, Access control System, building management system, Fire Detection & Alarm System, fire extinguishers and any other equipments/systems.

Design and Material

Walls and Ceiling

- Reinforce structure wall and ceiling panel suitable for negative pressure

- Sealed Airtight and chemical resistant

- Radius coving are installed at wall-to-wall, wall-to-ceiling.

Doors

- Lockable, airtight and self closing doors

- Entrance doors are interlock with emergence manual override

- Emergency exit

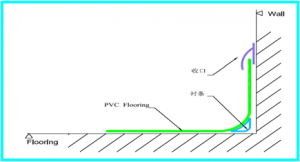

Floor

- Slip, abrasion and chemical resistant PVC floor

- All covered corner wall joint are carefully cut, formed and sealed

- Top coving strip, around the inner perimeter of the walls, is carefully sealed with RTV sealant

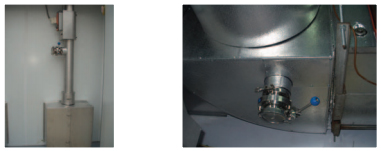

Pass through Box

- Made of stainless steel

- With mechanical interlocking

- Installed with UV sterilizer

- Double door autoclave is installed in the main laboratory for sterilization

- Double door interlock

- Unidirectional material flow from main laboratory to outside

Pass Box

- Pass through boxes are made of stainless steel with mechanical interlocking. Pass through boxes are installed with UV sterilizer.

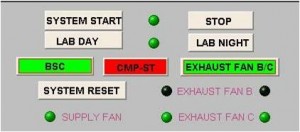

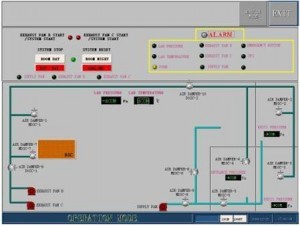

PLC Control

- Centralized Control

- Automatic Air Flow Control

- Pressure, Temperature & Humidity monitor and control

- HEPA filter resistance monitoring

- Round the clock (24 hours 7 days) monitoring, record and review of all parameters

- Remote monitoring via internet

- CCTV surveillance

User Interface

- Operator Mode – easy to use interface for daily operation

- Service Engineering Mode and Alarm Display Mode – makes maintenance and diagnosis accessible

HVAC System

HEPA Filter

- All air supply and exhaust are HEPA filtered

- HEPA filter of 99.99% filter efficiency of 0.3um particle size

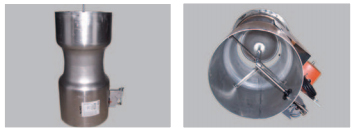

BAG IN BAG OUT

- Built at the room exhaust point and main exhaust point

- 99.99% filter efficiency of 0.3um particle size

- Completely airtight

- Easy for maintenance

Supply and Exhaust System

- Independent supply and exhaust system

- Unidirectional inward air flow

- None-recirculation, 100% total exhaust

- Sealed and air tight, stainless stell made all welded ducting

- Digital pressure gauges to measure and monitor pressure

- Equipped with high-performance valve to control the negative pressure stable

- Equipped with audible alarm to detect any pressure and temperature failure

- Equipped with air tight damper to permit airtight for decontamination

Easy Maintenance

Digital pressure gauges to measure and monitor HEPA resistance. If the resistance reaches the limitation for filter well-work, visual alarm in User Interface will remind to replace a new filter.

Spare spaces have been left in design for the purpose of changing HEPA filter, cleaning air duct and maintenance of equipments.

Waste water treatment

Waste water treatment system is equipped with chemical waste water treatment system for wate water generated from the laboratory. The whole treatment procedure can be accomplished automatically using chemical disinfectant.

Uninterrupted Power Supply/UPS

Uninterrupted power supply system is designed to provide continuous power to damper, controls and biological safety cabinet in the event of power failure from the source/city. Holding time can be selected to provide sufficient time to execute emergency protocol or activate backup electrical generator.

Standby exhaust blower

Standby exhaust blower is designed to switch on almost instantaneously when the original exhaust fails, ensuring the room maintains negative pressure.

Decontamination

The system is designed for easy decontamination. Regular decontamination service is provided during the defect liability period/warranty period.